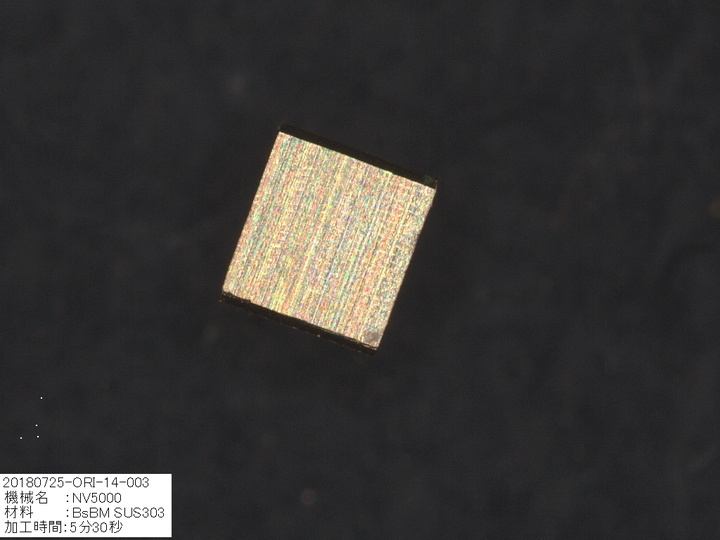

Parts Manufacturing System with Repeat Accuracy within 0.003mm (verified)

Accuracy Verification of 1mm Cubes and Others

At Saitama Industrial Technology Center, the following three verification test was performed.

1) Shape measurement using 3D X-ray CT measuring device

2) Measurement using non-contact micro-shape measuring device

3) Analysis of measured data

1) Shape measurement using 3D X-ray CT measuring device

2) Measurement using non-contact micro-shape measuring device

3) Analysis of measured data

Measuring instrument used:

– Carl Zeiss 3D X-Ray industry tomography system METROTOM 800

– Taylor Hobson white-light interference microscope Talysurf CCI 6000

Indoor temperature: 20±1 degree centigrade

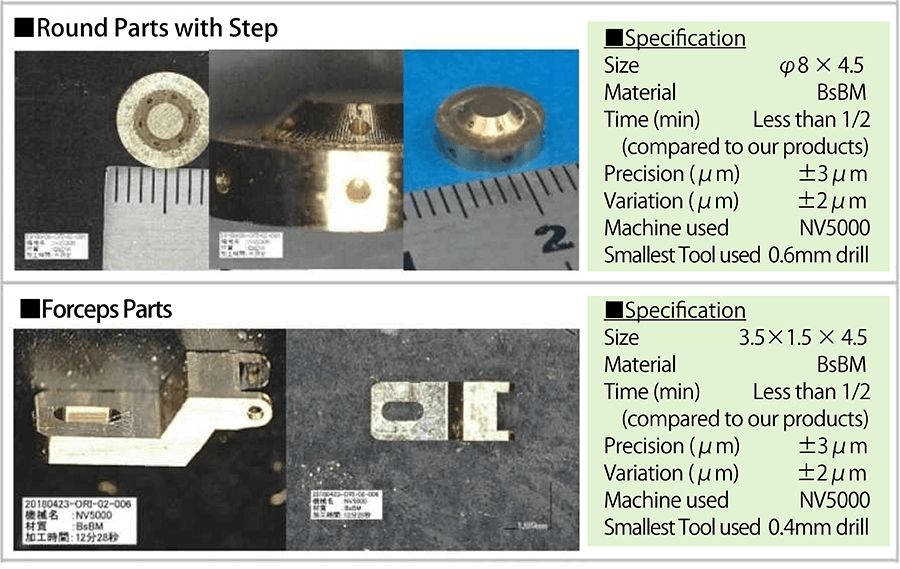

Verification Results

Round Parts with Step and Forceps Parts

Other Micro-Machining Challenges

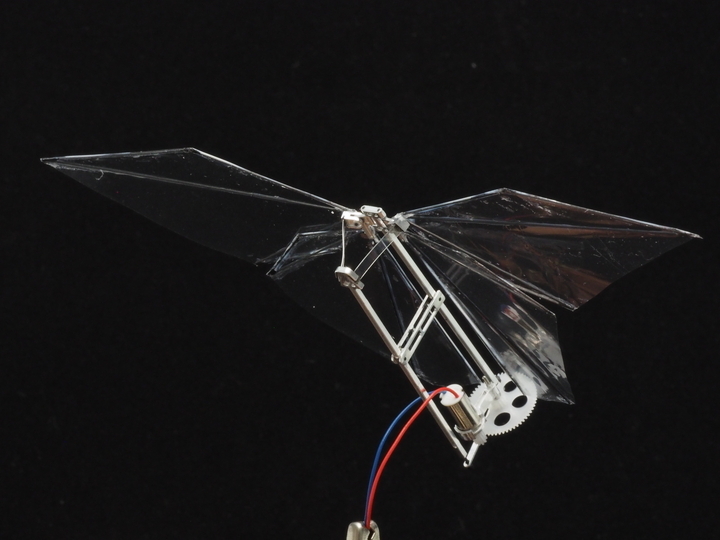

Small-sized Butterfly-style Flapping Robot

(Taro Fujikawa Laboratory, Tokyo Denki University)

World’s smallest universal joints were used, enabling light weight with sufficient stiffness.

Details >>

Parts Manufacturing System with Repeat Accuracy within 0.003mm (verified)

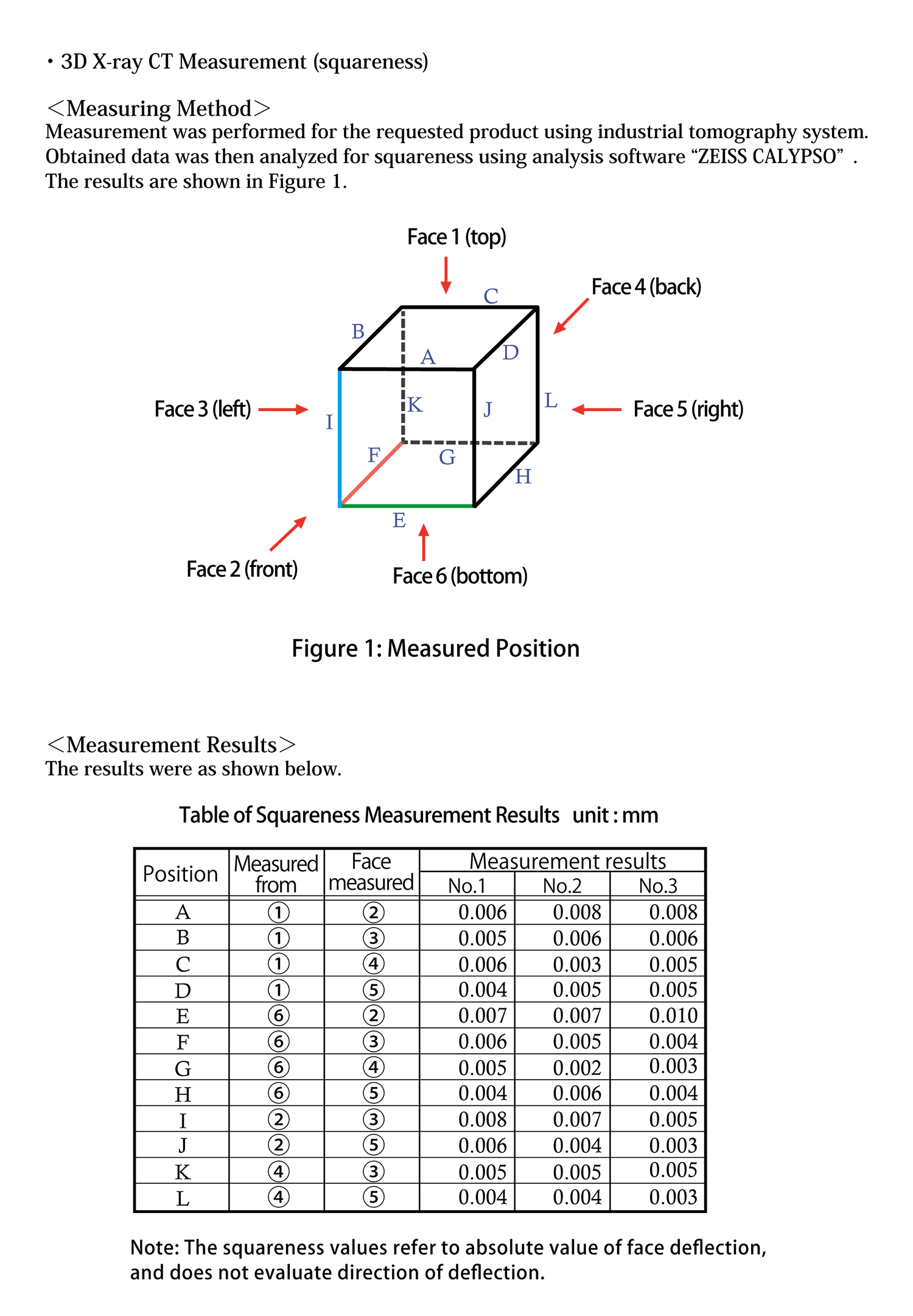

Analysis was performed to verify accuracy of 1mm cubes, cylinders, and forceps produced using ORIGAMI, and 0.008mm accuracy was verified.

Details >>

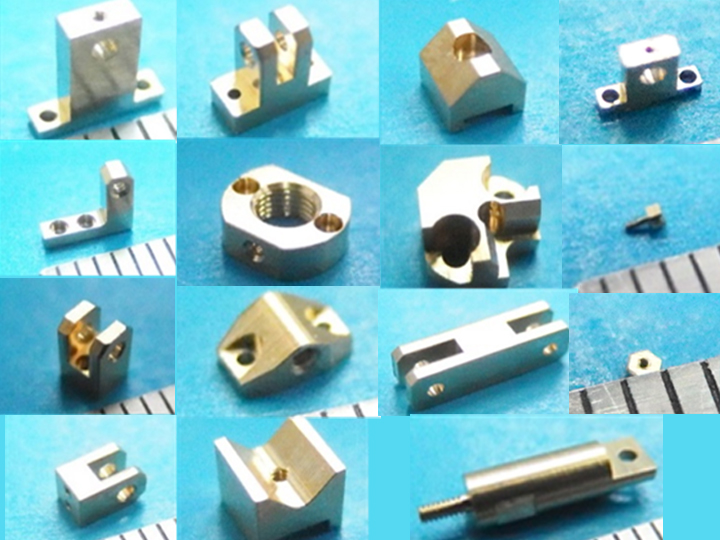

Micro Manufactured Product Examples

Planet gears, shaft holders, bolts, and other micro part product examples are listed here.

Details >>

The measurement results can be downloaded.

The measurement results can be downloaded.