The future of “mono-zukuri (product making)” will be driven by micro-machining.

To unleash conscious or subconscious restriction on development of production technology to support product making and service initiation efforts.

When technology is developed to allow commercial manufacturing of microscopic parts that was thought to be far beyond our technical capability, what innovations will occur in production for a variety of industries, such as medical service, space technology, and IT?

“mono-zukuri (product making)” starts with designing activity. In practice, however, the activity – especially conception of a design idea – is restricted by machining and other production technologies available in the downstream process. Things would be substantially different if a component can be made much lighter in weight with the same or more strength. Or if a component that is currently assembled from various parts is made by integral molding?

For instance, we see so-called minimum invasive medical devices, such as nano robots that are capable of entering a blood vessel and making microscopic treatment, belong to the world of science fiction. Or wearable IT equipment that does not disturb with human sensitivity, or optical equipment with minimum energy consumption. If our inspiration is liberated becoming free from traditional restrictions, a great variety of goods and services will become available to improve quality of living.

Any product that can change the world is always born as a result of an audacious attempt in a small lot. We believe that innovation of machining technology is the initial step to make a breakthrough in product design by overcoming a technological barrier that was considered impossible to surmount and making creative conception of products and services feasible in the manufacturing industry.

Project 01

Challenging to the Leading-edge Micro Machining Technology

We have been proving, through a number of unprecedented attempts in the world, that we are capable of overcoming the limits for micro machining technology.

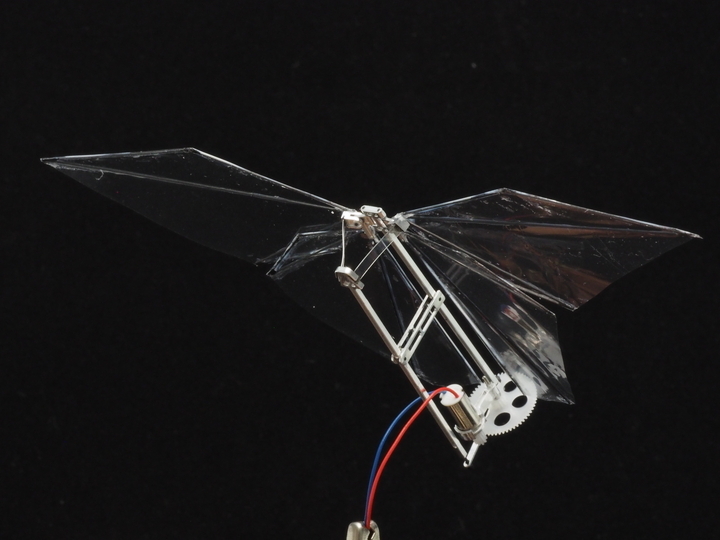

Butterfly-style Flapping Robot

(Fujikawa Lab, Tokyo Denki University)

Butterfly-style Flapping Robot uses universal joints smallest in the world, which enables lightweight still keeping sufficient stiffness in the small flying robot.

Details>>

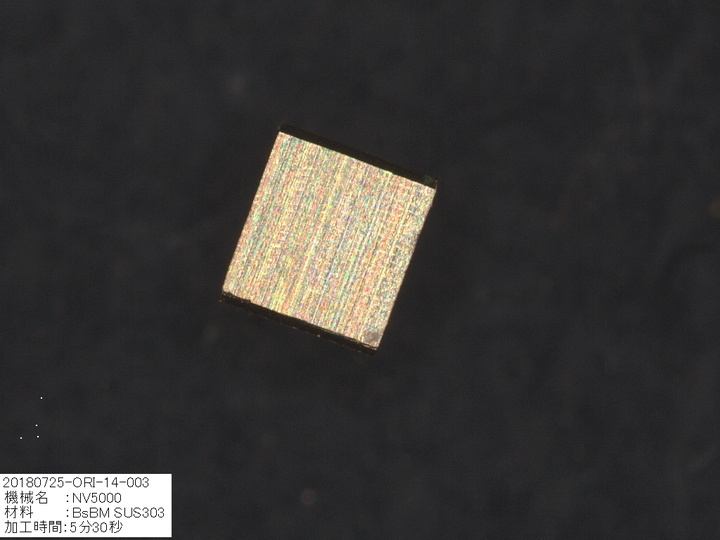

Parts Manufacturing System with Repeat Accuracy within 0.003mm (verified)

Analysis was performed to verify accuracy of 1mm cubes, cylinders, and forceps produced using ORIGAMI, and 0.003mm* accuracy was verified. (* The sample was created as test product at Iriso Seimitsu Co., Ltd., and the accuracy values are not listed as guarantee of manufacturing precision of ORIGAMI.)

Details>>

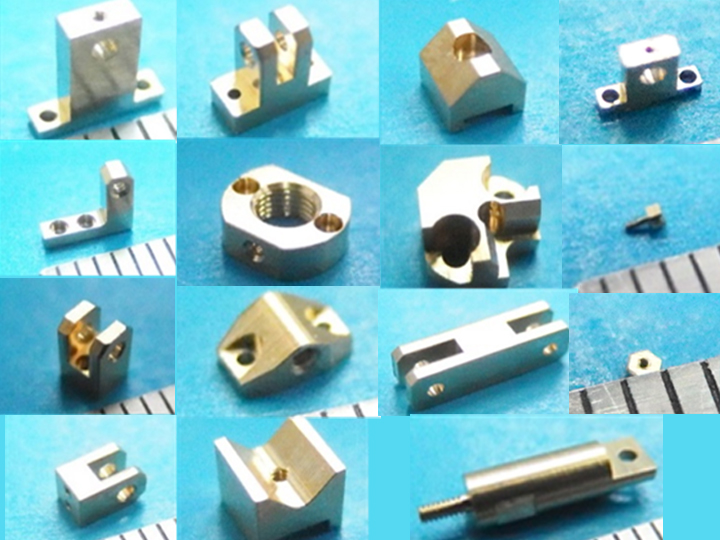

Micro Manufactured Product Examples

Planet gears, shaft holders, bolts, and other micro part product examples are listed here.

Details>>

Project 02

Development of Micro Machining Tools

Development of Products Transforming Small Town Factories to Leading-edge Technology Centers

Generally, it is believed that micro-machining requires highly costly and delicate operation and management together with a large-scale production system.

Iriso?? challenges this misconception in belief that small town factories, which serve as the core of industrial production, are capable of supporting the next-generation machining process. Through a firm commitment and support, we have been developing the series of machines and tools to support micro machining, which can be easily implemented by small town factories.

Double-wrist Robot inside Vertical 3-axis MC

ORIGAMI

For precise micro manufacturing, control of minimal shakes of cutting tools deserves utmost attention.

Easy NC Machine-Accuracy Measurement

BLAZE

For precise micro manufacturing, control of minimal shakes of cutting tools deserves utmost attention.

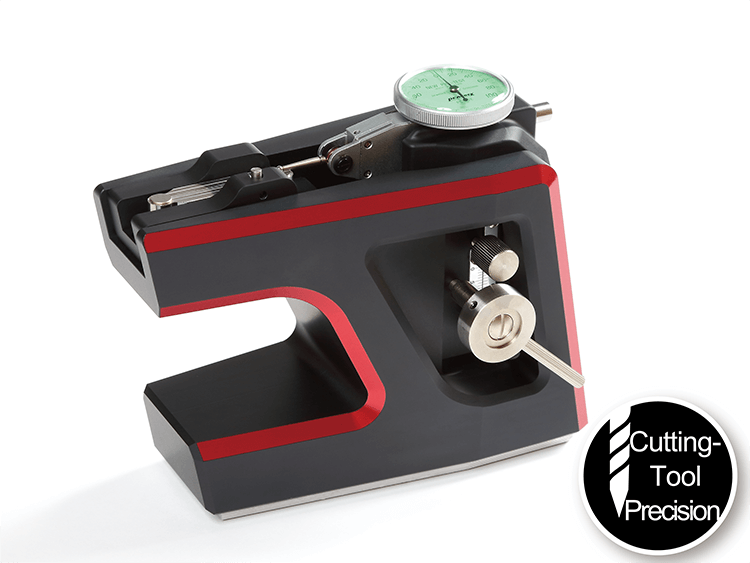

Contact Length Measurement for Small Cutting Tools

HAGOROMO

It softly touches the cutting tool, and measures the length within 0.003mm precision. Even 0.01mm fie endmills can be calculated safely.

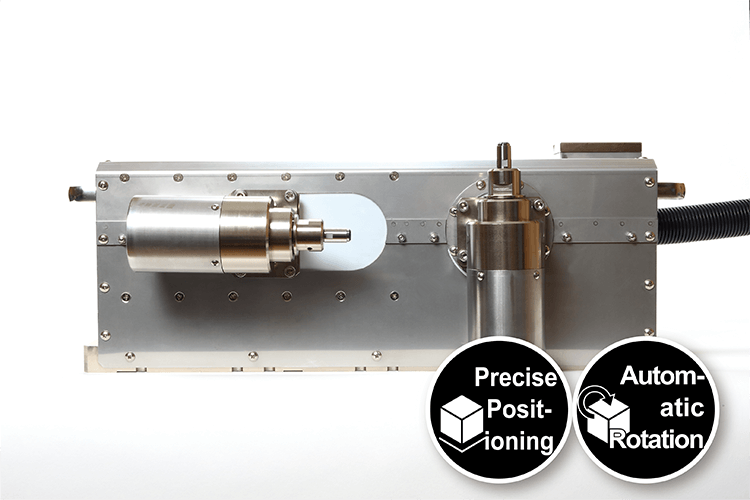

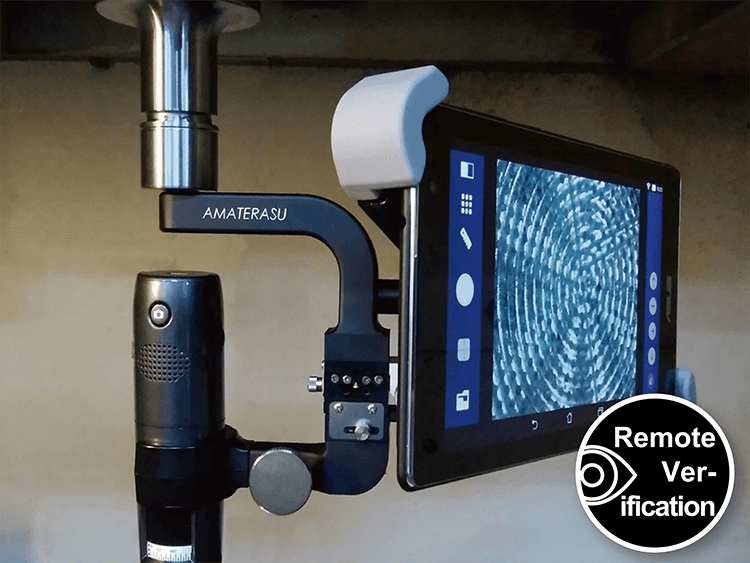

Spindle Camera in Machining Center

AMATERASU

Machine spindles will have “eyes” to record works inside machining centers. No need to take out the work to check. Can be operated the same way as cutting tools.

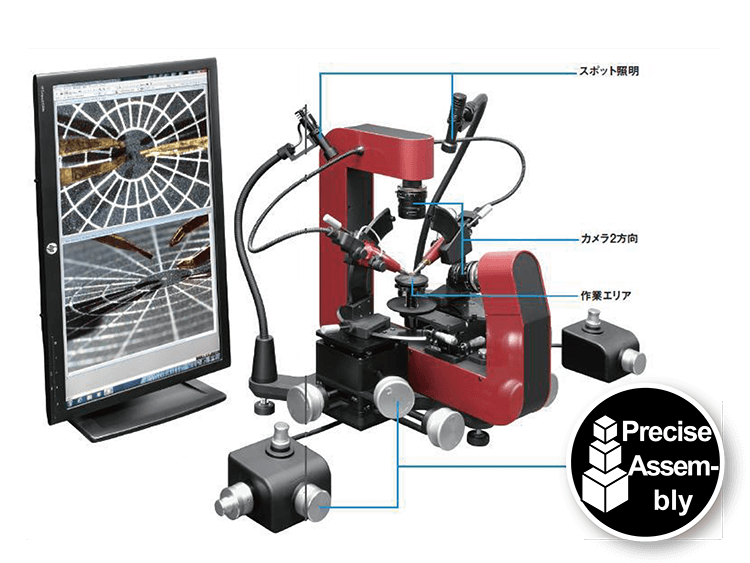

Handling Device for Ultrafine Workpieces

Micro Parts Handling System

This device offers easy assembly of parts difficult to see with human eyes, less than 0.3mm in size. New possibilities ahead for products less than 1mm.