Research

What exactly is iMC Research that would lead to micromachining?

iMC (integrated Machining Center) Research

What is integrated Machining Center (iMC)? A system to fabricate a product by means of integrated and composite management of conditions and phenomena related to the machining center to effectively control data-driven machining technology to its (minimum-level) limitation.

We actualize precision micro-machining in invisible size by measuring and monitoring related conditions and phenomena, such as precision positioning of a material and physical characteristics of a cutting tool, to an extent and level not ordinally aware of, thereby controlling relevant external factors.

We are committed to leading technological innovations in the manufacturing sector by transforming a small-town factory to a leading-edge technology development center. The key element is the machining center that has excellent processing capabilities, such as a high degree of adaptability to a wide variety of materials and quick machining time.

What exactly is iMC Research that would lead to micromachining?

Our idea of “iMC Machining Center” enables managamenet of relevant external factors of micromachining which was not taken care of seriously until then.

Details >>

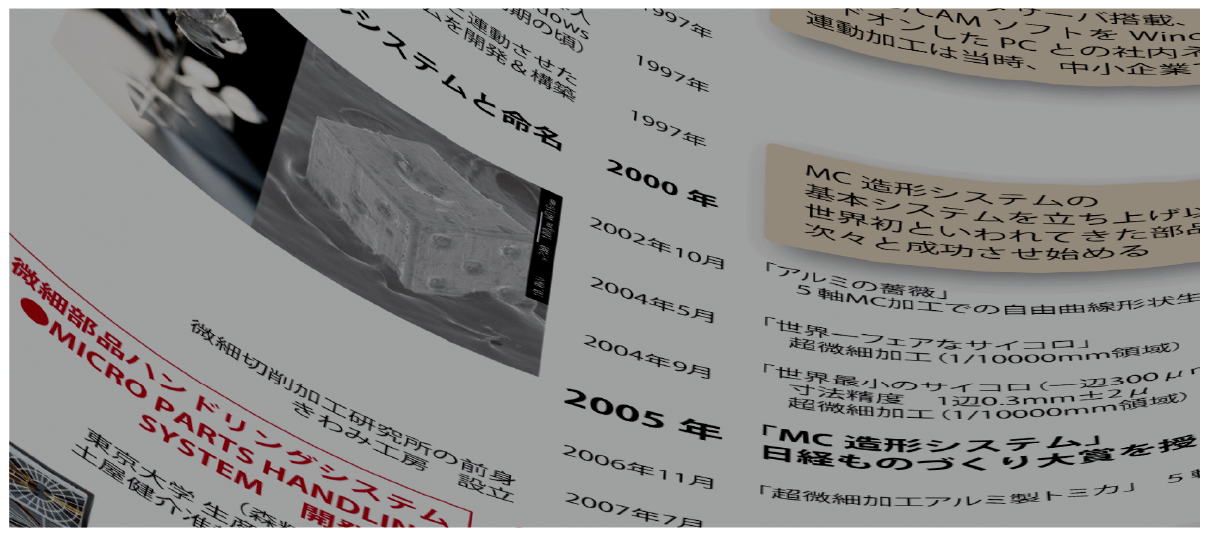

History of Research on Micro-Machining

We have been developing a new production process using machining centers since the 1990s, which crosses over and connects relevant fields, i.e., mechanical engineering, study on physical property, machining, and 3D data, for the purpose of developing machine tools that meet the needs of the production floor.

Details >>

Research, Patent, Papers, Lectures

Click here for past research, patent, paper, and lecture information.

Details >>